The helium mass spectrometer leak detection method utilizes the helium partial pressure measurement principle of the helium mass spectrometer leak detector to measure the helium leakage amount of the inspected object. When there is a leak on the sealing surface of the inspected part, the leak gas helium and other components of the gas will leak out from the leak. After the leaked gas enters the helium mass spectrometer leak detector, due to the selective recognition ability of the helium mass spectrometer leak detector, only the partial pressure signal value of helium in the gas is given. On the basis of obtaining the helium signal value, the helium leakage rate can be obtained by comparing the standard leakage holes.

According to the different relationships between the storage location of the leak gas and the inspected object during the leak detection process, helium mass spectrometry leak detection methods can be divided into vacuum method, positive pressure method, vacuum pressure method, and back pressure method. Below, Fuyuanda summarizes the detection principles, advantages and disadvantages, and detection standards of these four helium mass spectrometry leak detection methods.

Vacuum helium mass spectrometry leak detection

When using the vacuum method for leak detection, it is necessary to use an auxiliary vacuum pump or leak detector to evacuate the sealed chamber inside the tested product. Helium gas is applied to the outer surface of the tested product using a helium hood or spray method. When there is a leak hole on the surface of the tested product, helium gas will enter the interior of the tested product through the leak hole and then enter the helium mass spectrometer leak detector to measure the leakage amount of the tested product. According to the different methods of gas leakage, vacuum method can be divided into vacuum injection method and vacuum helium hood method. The vacuum spraying method uses a spray gun to spray helium gas onto the outer surface of the inspected product, which can achieve precise positioning of the leakage hole; The vacuum helium hood method uses a helium hood with a certain sealing function to cover all the tested products, and fills the hood with a certain concentration of helium gas, which can achieve the measurement of the total leakage rate of the tested products.

The advantages of vacuum method are high detection sensitivity, precise positioning, and the ability to detect leaks in large containers or complex structural products.

The disadvantage of vacuum method is that it can only detect the leakage rate of one atmospheric pressure difference, and cannot accurately reflect the true leakage state of the product under pressure.

The detection standards of vacuum method mainly include QJ3123-2000 "Helium Mass Spectrometry Vacuum Leak Detection Method" and GB/T 15823-2009 "Helium Leakage Inspection", which are mainly used for products that require vacuum sealing performance but do not work under pressure, such as space moving parts, liquid hydrogen tank trucks, environmental simulation equipment, etc.

Positive pressure helium mass spectrometry leak detection

When using the positive pressure method for leak detection, it is necessary to fill the sealed chamber inside the tested product with helium gas at a pressure higher than one atmosphere. When there is a leak on the surface of the tested product, helium gas will enter the surrounding atmosphere through the leak hole and then use a suction gun to detect the increase in helium concentration in the surrounding atmosphere of the tested product, thereby achieving leak measurement of the tested product. According to the different methods of collecting helium gas, the positive pressure method can be divided into the positive pressure suction gun method and the positive pressure accumulation method. The positive pressure suction gun method uses a leak detector suction gun to scan and explore the outer surface of the inspected product, which can achieve precise positioning of the leakage hole; The positive pressure accumulation method uses a helium cover with a certain sealing function to cover all the tested products, and uses a leak detector suction gun to measure the change in helium concentration inside the helium cover before and after a certain period of time, achieving accurate measurement of the total leakage rate of the tested products.

The advantage of the positive pressure method is that it does not require an auxiliary vacuum system and can accurately locate and detect under any working pressure.

The disadvantage of the positive pressure method is that it has low detection sensitivity, high uncertainty in detection results, and is greatly affected by measurement environmental conditions.

The testing standards for positive pressure method mainly include QJ3089-1999 "Helium Mass Spectrometry Positive Pressure Leak Detection Method" and QJ2862-1996 "Helium Mass Spectrometry Suction Gun Cover Box Leak Detection Test Method for Pressure Vessel Welds". It is mainly used for leak detection of large volume high-pressure sealed container products, such as high-pressure helium cylinders, cabin door leak detectors, etc.

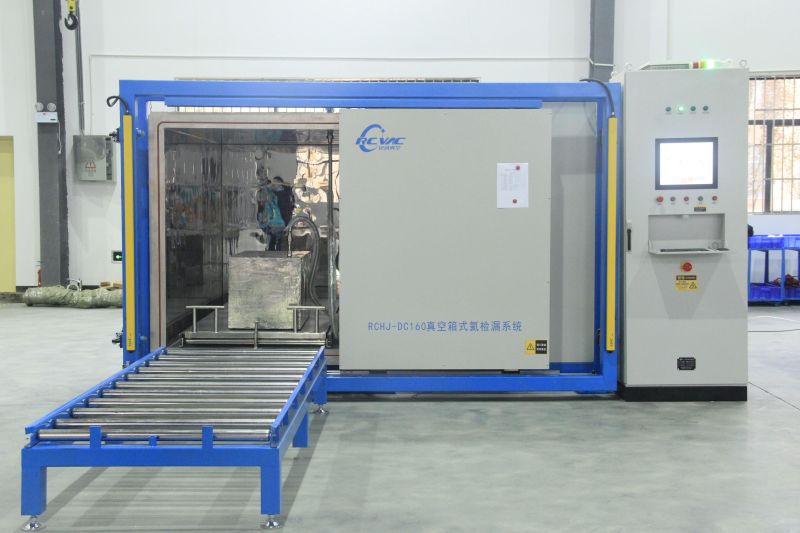

Vacuum pressure method helium mass spectrometry leak detection

When using the vacuum pressure method for leak detection, the inspected product needs to be placed as a whole in a vacuum sealed chamber, which is connected to the auxiliary evacuation system and leak detector. The inflation interface of the inspected product is led out of the vacuum sealed chamber through a connecting pipeline and then connected to a helium gas source. When there is a leak hole on the surface of the inspected product, helium gas will enter the vacuum sealed chamber through the leak hole and then enter the helium mass spectrometer leak detector to measure the total leakage rate of the inspected product.

The advantage of the vacuum pressure method is its high detection sensitivity, which can detect the leakage rate of any working pressure and reflect the true leakage state of the inspected object.

The disadvantage of the vacuum pressure method is that the leak detection system is complex and requires the design of a vacuum sealed chamber based on the volume and shape of the product being tested. It should be noted that during the leak detection process, it is required to ensure that there is no leakage at the inflation pipeline interface, or to adopt a special structural design to place all inflation pipeline connection interfaces outside the vacuum sealed chamber.

The detection standard for vacuum pressure method includes GB/T 15823-2009 "Helium Leakage Inspection", which is mainly applied to sealed products with simple structure and not particularly high pressure, such as solenoid valves, high-pressure inflation pipelines, propellant storage tanks, antennas, responders, and whole satellite products.

Back pressure helium mass spectrometry leak detection

When using the back pressure method for leak detection, the tested product is first placed in a high-pressure helium chamber and soaked for several hours or days. If there are leakage holes on the surface of the tested product, helium gas is pressed into the internal sealing chamber of the tested product through the leakage holes, causing the helium partial pressure in the internal sealing chamber to rise. Then take out the inspected product, blow off the residual helium gas on the surface, and place the inspected product in a vacuum container connected to the leak detector. The helium gas inside the sealed chamber of the inspected product will leak into the vacuum container through the leak hole, and then enter the helium mass spectrometer leak detector to measure the total leakage rate of the inspected product. The leakage rate value given by the leak detector is the measured leakage rate, and the equivalent standard leakage rate of the tested product needs to be calculated through a conversion formula.

The advantage of back pressure method is high detection sensitivity, which can achieve leak detection of small sealed container products and enable batch testing.

The disadvantage of back pressure method is that it cannot leak large sealed containers, otherwise the pressurization time will be too long due to the large volume of the sealed chamber. In addition, each measurement leakage rate corresponds to two equivalent standard leakage rates. After the fine inspection is completed, other methods need to be used for rough inspection to eliminate the possibility of large leakage.

The leak detection standards for back pressure method mainly include QJ3212-2005 "Helium Mass Spectrometry Back Pressure Leak Detection Method" and GJB360A-1996 "Electronic and Electrical Component Test Method Method 112 Sealing Test", which are mainly used for leak detection of various electronic component products.

首页

首页 核心产品

核心产品 电话咨询

电话咨询 技术团队

技术团队